Page 3 of 4

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 03 Jun 2018 18:07

by GasGuzzler

I have two kinds of Lyman media. Neither has produced shiny brass but one plugs flash holes. No pin wet tumbling leaves my stuff as clean or cleaner than what you show there except the pocket. It looks like yours before prep center. That is fine for my use.

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 03 Jun 2018 18:10

by GasGuzzler

You should see my .357/A2400 cases. Greasy for sure. Greasy and accurate.

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 03 Jun 2018 19:16

by mr surveyor

Being "thrifty" (actually cheap, especially recently), I'm still using my 35 year old ultrasonic drafting pen cleaner for all my brass. I don't do a lot, but I usually come in from a shooting trip and deprime and clean them same day or next day. Being a small tub US cleaner, I only do 20 to 40 in a batch, but I've found that just a dash of Lemi-Shine and a couple drops of Dawn will keep them in a manageable condition with only around a 10 minute run. Since I'm already doing other things anyway, it's no big deal to take those out and dump in another batch. They sure aren't "shiny" after 8 or 10 uses, but they stay clean.

jd

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 05 Jun 2018 16:42

by EdgeOfEden

I think any method that works for you is the appropriate choice.

I had put off wet tumbling with pins, but again with everyone raving about it, I thought I'd give it a go. While I have always been pleased with the external results of dry tumbling with case polish, I have to admit that I liked the results of wet tumbling with pins when it came to the primer pockets and inside the cases.

With the stray pins that Ranch Dog and others have discovered while reloading, I am wondering what methods were employed for separating the pins from the brass. I have been using the Lyman Rotary Case Media separator. These are my steps after wet tumbling with pins:

1. Fill the Lyman separator with about 3/4 full of water.

2. Pour off most of the filthy water and dump the pins into the basket over the water

3. Spin the basket several times one way and then the opposite. I repeat this cycle for 1 to 2 minutes.

4. Pour off most of the water out of the Lyman Separator and transfer the separated pins into the storage container with a Frankford Arsenal Magnet. (I re-rinse the pins later)

5. Empty the remaining water and add fresh.

6. Repeat the spin process and remove any additional pins that separate. I usually have none, but never more than 2 or three.

7. Remove the cases from the basket and place in a dryer.

Using this method I have never found any stray pins left in the cases. Have I just been fortunate? Is my time still coming? Is there a better method?

With the wet tumbling steps I take It should be obvious that, if you are going to consider hands-on time, dry tumbling is way faster than wet tumbling. I think which is better is simply a matter of preference. Frankly I like both methods but for different reasons.

While I haven't tried wet tumbling without pins, I believe at some point I'll give it a try for .223/5.56 and check out the results. I've got the stuff--why not?

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 05 Jun 2018 23:03

by Fyodor

RD had the problems with very small bottleneck cases. They seem to have an inner diameter that's pretty identical to the length of the pins. In that case, they indeed can get stuck hard. I never had cases that small, and when the pins are a bit shorter than the inner diameter, this can't happen.

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 06 Jun 2018 05:46

by Ranch Dog

East of Eden wrote:With the stray pins that Ranch Dog and others have discovered while reloading, I am wondering what methods were employed for separating the pins from the brass. I have been using the Lyman Rotary Case Media Separator.

I used a similar device, the Frankford Arsenal Quick-n-EZ Rotary Sifter (middle) and a similar procedure to yours.

Going to the corncob reminded me how simple it once was. Shake a basket for less than a minute, and it's done.

Fyodor wrote:RD had the problems with very small bottleneck cases. They seem to have an inner diameter that's pretty identical to the length of the pins. In that case, they indeed can get stuck hard. I never had cases that small, and when the pins are a bit shorter than the inner diameter, this can't happen.

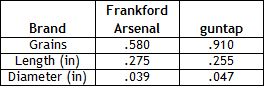

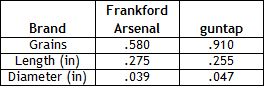

Fyodor hit the problem with the 218 Bee cases. I should have stuck with the Frankford Arsenal pins and not mixed in the GunTap.

This chart is from

Steel Pin Cleaning

In that post, I had mentioned that I had bought the guntap detergent and was pleased with it. That changed with the trial I just ran with the 32-20 Win cases. Their detergent might be great for producing a shine, but it did not cut the alox grease at all. Instead, the grease spread over brass and pins completely.

This is one of those trials where I end up with the SS Pin t-shirt so I'm good with the old method. Less mess and time by a long shot.

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 06 Jun 2018 06:38

by EdgeOfEden

Ranch Dog, other than the sifter our wet tumbling setup is the same. I've not used any other pins than the FA pins; so I guess if I'm going to continue to tumble .223/5.56 with pins, it would behoove me to stay with the FA pins or shorter.

My pistol ammo has all been dry tumbled. I take it outside and sometimes wear a mask to avoid breathing in the lead contaminated dust. With my plinking pistol ammo, dry tumbling has been more than adequate and I see no reason to change. Truth is reloaders got along just fine for years and years before the "it's gotta shine" syndrome. Our targets are not only press-blind they are shine-blind.

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 06 Jun 2018 08:36

by daboone

I'm not giving up on SS pins. I admit I'm not a high volume reloader so sorting out and inspecting each case after tumbling isn't all that odorous to me. That said I only SS pin new found range brass or when the primer pockets start looking nasty. Corn cob media in a buzz bucket is simply faster and easier to do. Add to that I'm lazy so the buzz bucket method of cleaning is done to remove the sizing lube after a batch has been completely reloaded.

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 06 Jun 2018 18:15

by GasGuzzler

I still don't understand how picking dry media out of nearly every flash hole and having dusty cases that must then be washed with liquid then dried is easier or faster than just washing and drying the cases in the first place. I don't use pins. Dry tumbling for 12 hours produced brass 80% as clean as no-pin wet tumbling for 30 minutes.

Re: Rethinking Steel Pin Cleaning & Annealing

Posted: 06 Jun 2018 21:07

by EdgeOfEden

GasGuzzler wrote:I still don't understand how picking dry media out of nearly every flash hole and having dusty cases that must then be washed with liquid then dried is easier or faster than just washing and drying the cases in the first place.

Dry tumbling my pistol cases in walnut w/case polish and then spinning in the Rotary Media Separator has not yet resulted in the condition you describe. In addition, I add used dryer sheets cut in strips to the vibratory tumbler, which cuts down on dust and I also add them to the separator. I have never needed to wash the cases afterwards. When I use the rotary separator, I give it a good long churning. Up to this point, I just haven't had any problems and I've never had to wash the brass after tumbling. I'm not even that concerned with a stuck piece of media in the flash hole as the case is going to be deprimed anyway. I'm also far less concerned with a piece of walnut vs a stainless steel pin. I also quickly inspect all my cases whether they are dry or wet tumbled.

GasGuzzler, as I indicated in a previous post I intend to try wet tumbling once without SS pins for my .223/556 for comparison at some point in the future to compare results. I'm also for whatever works for the individual reloader. Ain't freedom grand?