Expander Diameter Matters!

Posted: 28 Feb 2016 08:15

I started working with my SMLE chambered in 303 British and noticed that as I started to chamber some test cartridges that I was getting some bullet slip as the bolt was rotated closed. With the short necked 303 British, the bullet was remaining stationary but the case was rotating and despite the positive crimp with the Factory Crimp Die the bullet would slide to the forward edge of the cannelure as the bolt was closed. Using cartridges dipped in mica, I was able to verify the movement.

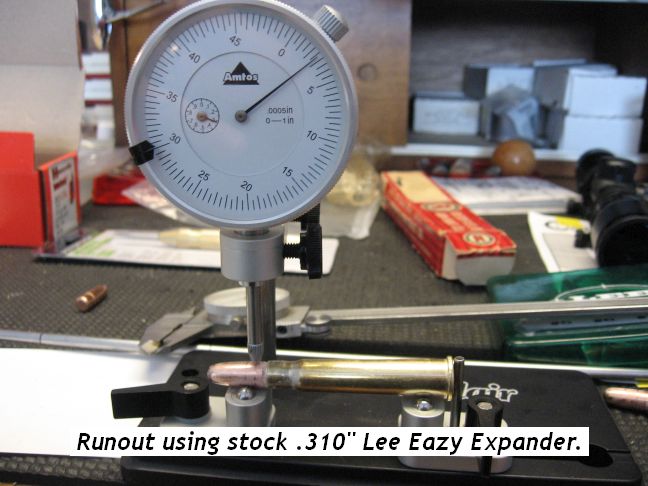

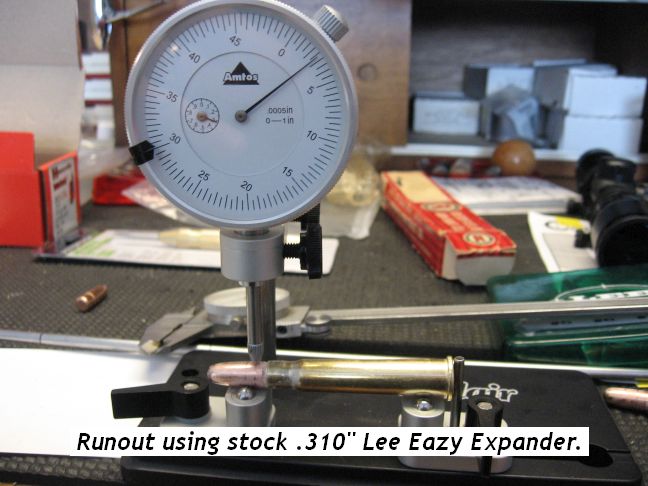

I also thought that for this movement to be taking place within the confines of the chamber, the seated bullet might not be concentric with the longitudinal axis of the case thus making contact with chamber walls in the process of the bolt rotation. Pulling out the cartridge runout scale told the tale. The 303 British die set uses a .310" expander and the short neck of the cartridge was just not providing enough alignment and tension. Average runout is as indicated, .0027". Onc hit with the kinetic bullet puller would send the bullet sailing.

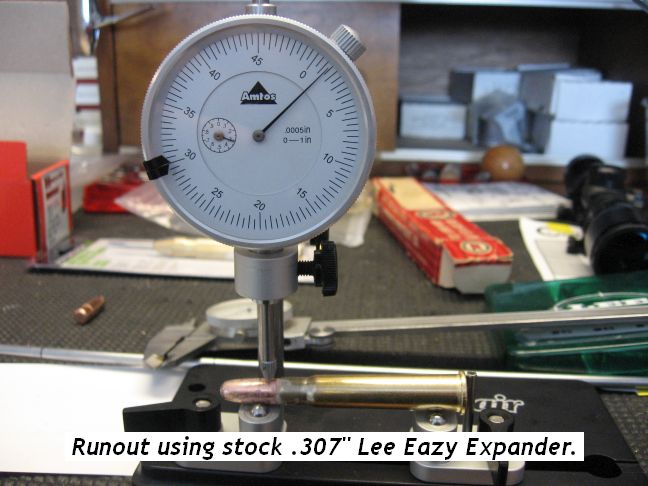

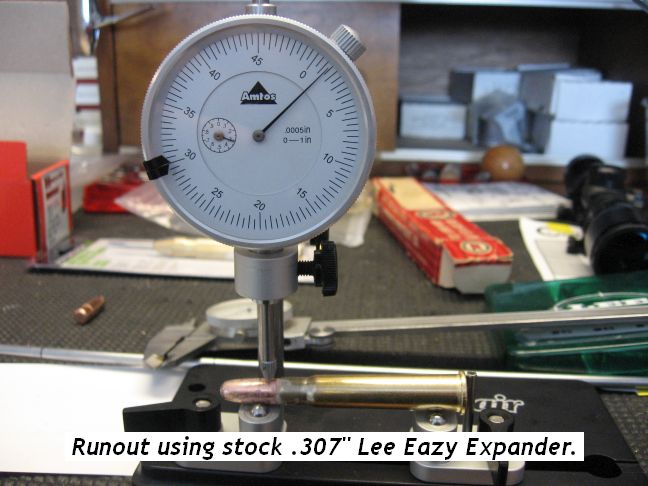

Lucky, I keep a stock of different expander diameters and the basic 30 caliber expander, a .307", provided great tension which eliminated the "slip" when chambering a cartridge and cut the average runout in half.

Will need to get a .002" undersized mandrell ordered for the collet die for use with jacketed bullets!

I also thought that for this movement to be taking place within the confines of the chamber, the seated bullet might not be concentric with the longitudinal axis of the case thus making contact with chamber walls in the process of the bolt rotation. Pulling out the cartridge runout scale told the tale. The 303 British die set uses a .310" expander and the short neck of the cartridge was just not providing enough alignment and tension. Average runout is as indicated, .0027". Onc hit with the kinetic bullet puller would send the bullet sailing.

Lucky, I keep a stock of different expander diameters and the basic 30 caliber expander, a .307", provided great tension which eliminated the "slip" when chambering a cartridge and cut the average runout in half.

Will need to get a .002" undersized mandrell ordered for the collet die for use with jacketed bullets!