I'm All In ~ App Press Deluxe

-

Tonerboy1

- Posts: 32

- Joined: 10 Nov 2019 16:25

- My Press Choice: Single Stage

- Location: MI

- Has thanked: 12 times

- Been thanked: 9 times

Re: I'm All In ~ App Press Deluxe

I finally got mine up and running for sizing PC'd 380 and 9mm. I had some really short flat nosed 380's that turned out a little tricky. They were so short I had to go with no guide on the pusher and still had problems with the pusher wanting to push the next bullet along with the current bullet from the feed tube. I would eventually slingshot the bullet across the garage when it would finally separate. I ended up beveling the front edge of the pusher so the second bullet would get pushed back up into the feed tube. This was all due to the bullet being so short. Then I switched to a little longer 380 and had to add the thinnest pusher guide on, readjust the drop tube. Those all sized great. Then went to a round nose 9mm. I was able to use the same pusher but had to again adjust the height of the drop tube. Each time the drop tube was adjusted it would take a few rounds to perfect the height so they would feed well. Once adjusted it worked pretty well with only an occasional goof up. As long as any flange on any bullet was not too pronounced they fed through the feed tube good, if one had too much flange you better just feed that one manually or you end up pushing it through with bullets behind it to keep it moving. I was able to feed bullets into the tube with my left hand as I cranked the lever with my right. since I am right handed I would fall behind eventually and use both hands to top off the feed tube. I have to admit its an interesting tool. The shortcomings for me Is I do a lot of different calibers and "small" runs of PC bullets in different colors, weights and calibers. There is a lot of "tinkering" with the mechanics of this "Automatic" press between changes. The stability of the plastic parts as they age is a question I have also. If I am changing the pusher guide height pieces a lot will they get brittle and break the clips? Will they break at a crutial time when I NEED the machine to do a certain size? I'm not sure I want to spend the money on an additional upgrade kit to have a second set of plastic parts sitting around just in case something happens. Plus I know plastic gets brittle just sitting around anyway. I don't want to sound too negative because I do like the press a lot, but time will tell how the plastic holds up and I definitely will not be getting rid of old faithful. She is just on another plate so I can switch back to her for some jobs this press will just not do. If I had a lot of money and could buy several of these and set up each to do a specific job and not have to re adjust everything in between OR if I did a lot of one thing at a time (several hundred of the same bullet size/shape) this would fit the bill for sure. I am still waiting on doing any case prep on this machine. Again that will entail changing the pusher height (plastic piece) feed tube height (a couple nuts to loosen/tighten) and coming up with some sort of bucket or "catcher" for the brass. Lee definitely filled a nitch with this press. I'm still not sure if its an all around press or one a new loader would want to learn beginning reloading on.

- Ranch Dog

- Site Admin

- Posts: 6457

- Joined: 22 Jun 2013 17:16

- My Press Choice: Progressive

- Location: Inez, TX

- Has thanked: 1617 times

- Been thanked: 2850 times

Re: I'm All In ~ App Press Deluxe

Great writeup Tonerboy! I haven't gotten into the bullet end of this press, but your findings and about fine adjustments beyond the basic lego work is my experience as well. Probably a great rule of thumb at this point of my experience level is that if you have anything less than a full tube of cases or bullets, just place them into position individually unless the feeder is already setup for that specific case or bullet.

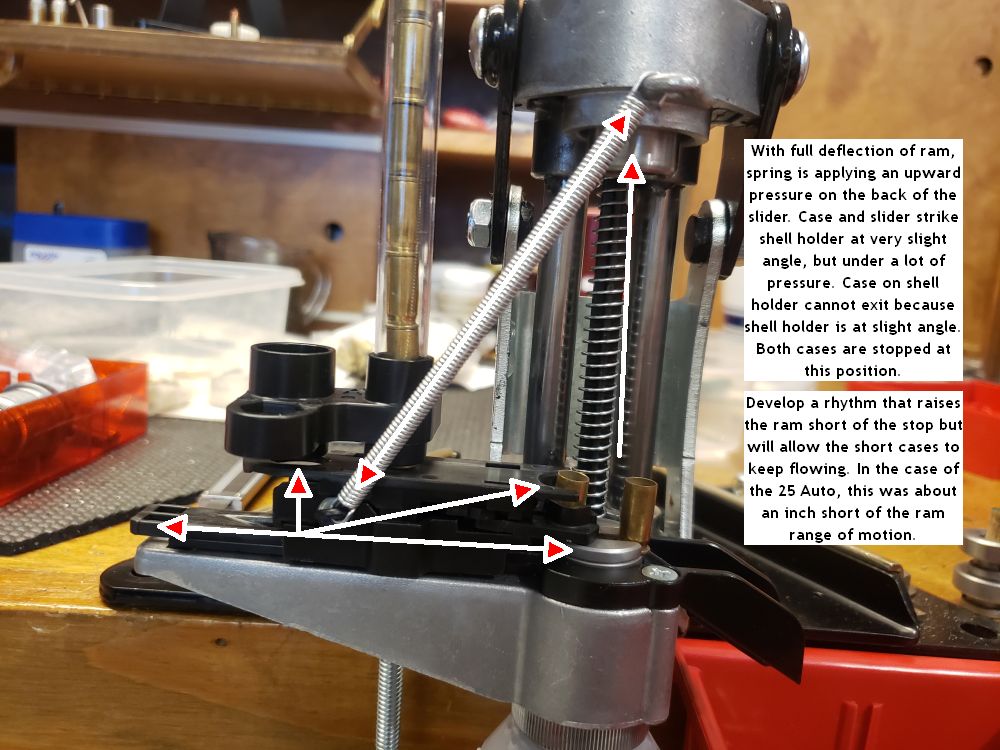

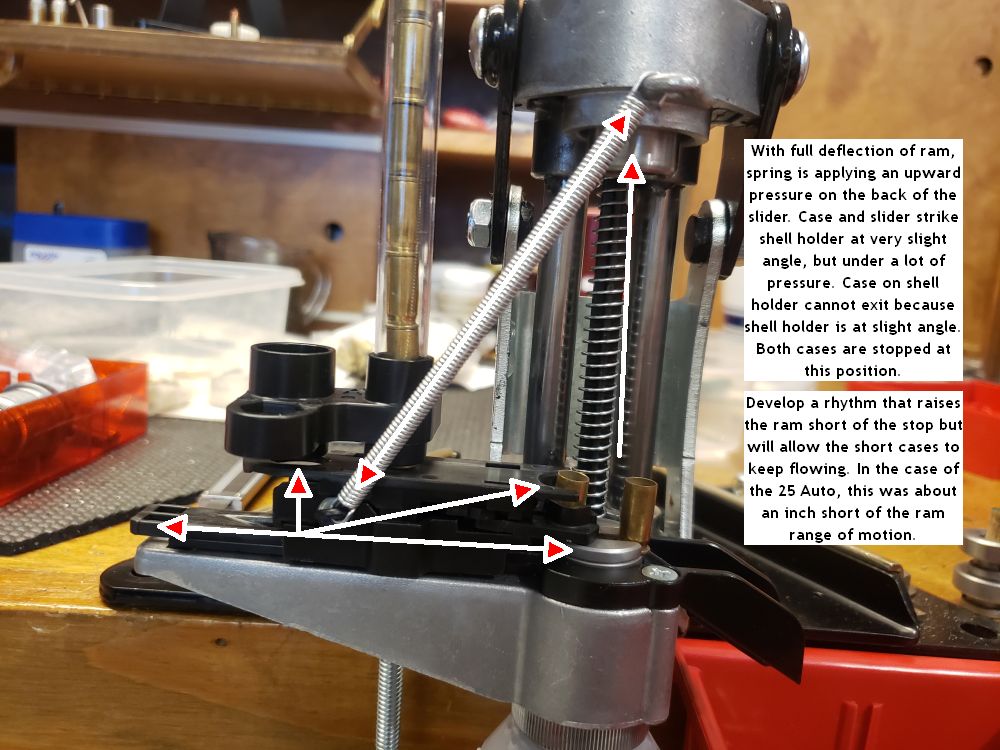

The little 25 Auto case really put a spotlight on some very small points about the feeder and press, this sounds like your short bullet experience. The main thing I'm taking away from reloading yesterday is not to use the full stroke of the press, only what is needed to keep things moving. After the handle has come all the way down and starting back up, an upward pull is applied to the tail of the slider as tool head moves toward its stop. The tail end of the slider is being lifted up by the spring and it starts to rub on the base of the feeder as the slider moves toward the shell holder.

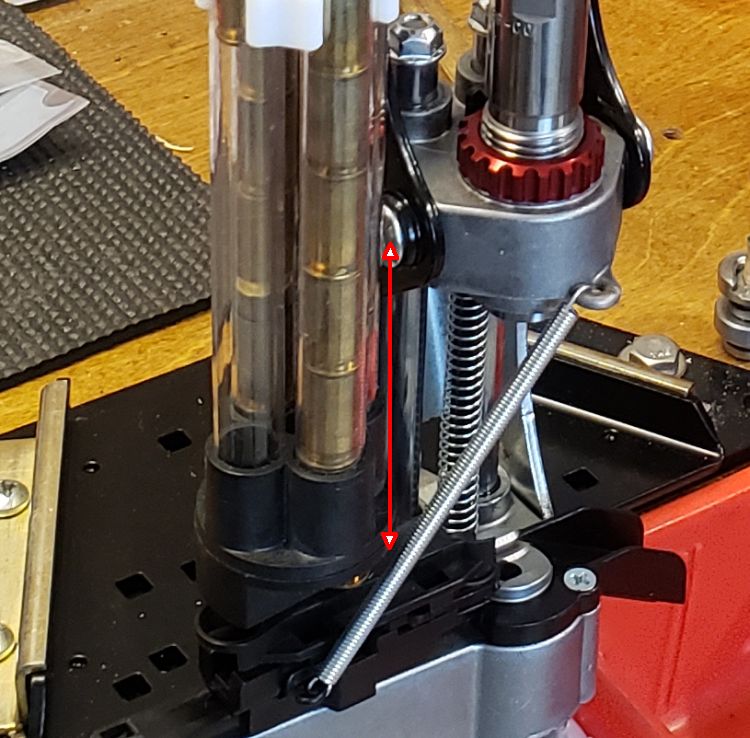

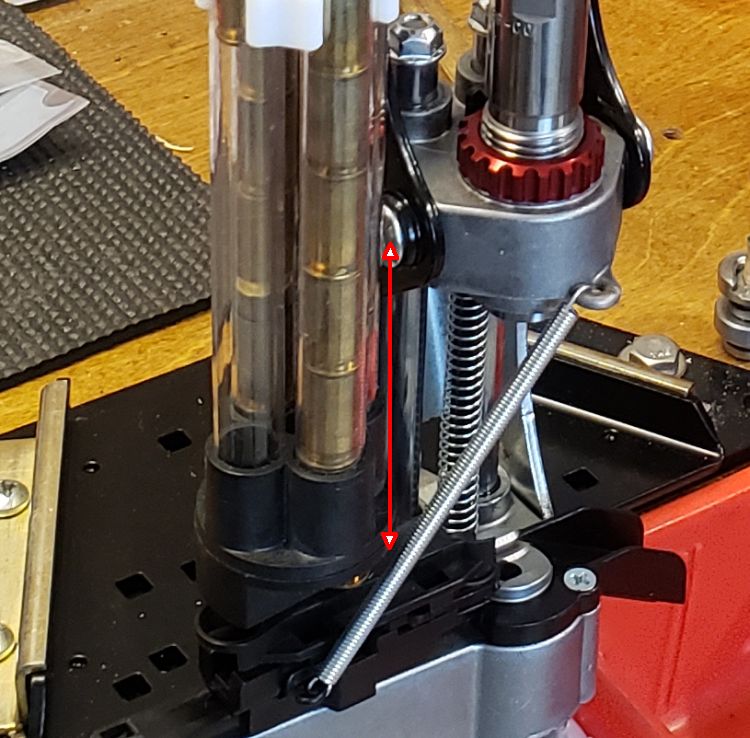

Honestly, the old version of the Multi-Tube Feeder is better than the newer single tube or Multi-Tube feeder because it sits closer to the press. It actually just bumps the handle's carriage bolt, but I found that keeps the collator in action and cases filling the tubes. This reduced distance means that the slider isn't going back as far nor is the spring under the tension that it experiences with the new feeders. You can see the position of the old Multi-Tube feeder.

Had this press come along a decade ago, I would probably have about four of them as this discussion is why I have four Load-Masters. Sure you can set one up, back and forth to work with different cartridges, but it literally can take a day to do it. My Load-Master fits a specific range of cartridges that I work with. Even then, I figure it takes about an hour to tune and test it after a cartridge change. I never plan on loading with it the same day, I like getting it ready at my leisure, and then start work when everything is together.

I got to go, more on the slider parts later. I think they are going to be needed at the bench.

The little 25 Auto case really put a spotlight on some very small points about the feeder and press, this sounds like your short bullet experience. The main thing I'm taking away from reloading yesterday is not to use the full stroke of the press, only what is needed to keep things moving. After the handle has come all the way down and starting back up, an upward pull is applied to the tail of the slider as tool head moves toward its stop. The tail end of the slider is being lifted up by the spring and it starts to rub on the base of the feeder as the slider moves toward the shell holder.

Honestly, the old version of the Multi-Tube Feeder is better than the newer single tube or Multi-Tube feeder because it sits closer to the press. It actually just bumps the handle's carriage bolt, but I found that keeps the collator in action and cases filling the tubes. This reduced distance means that the slider isn't going back as far nor is the spring under the tension that it experiences with the new feeders. You can see the position of the old Multi-Tube feeder.

Had this press come along a decade ago, I would probably have about four of them as this discussion is why I have four Load-Masters. Sure you can set one up, back and forth to work with different cartridges, but it literally can take a day to do it. My Load-Master fits a specific range of cartridges that I work with. Even then, I figure it takes about an hour to tune and test it after a cartridge change. I never plan on loading with it the same day, I like getting it ready at my leisure, and then start work when everything is together.

I got to go, more on the slider parts later. I think they are going to be needed at the bench.

Michael

- GasGuzzler

- Moderator & Supporter

- Posts: 2040

- Joined: 26 Jan 2016 22:39

- My Press Choice: Turret

- Location: Cooke County, TX

- Has thanked: 330 times

- Been thanked: 500 times

Re: I'm All In ~ App Press Deluxe

My accessories aren't here yet so I haven't set mine up but I did order a couple of these.Tonerboy1 wrote:coming up with some sort of bucket or "catcher" for the brass.

__________________________________________________________________________________________

I've always been crazy but it's kept me from goin' insane.

I've always been crazy but it's kept me from goin' insane.

-

klr

- 250 Shots

- Posts: 305

- Joined: 01 Mar 2016 05:00

- My Press Choice: Single Stage

- Location: ohio

- Has thanked: 108 times

- Been thanked: 94 times

Re: I'm All In ~ App Press Deluxe

I sure am glad to read this. I spent several hours both Saturday and Sunday night setting up my Loadmaster. Nice to know it's not just me.Ranch Dog wrote:

Had this press come along a decade ago, I would probably have about four of them as this discussion is why I have four Load-Masters. Sure you can set one up, back and forth to work with different cartridges, but it literally can take a day to do it. My Load-Master fits a specific range of cartridges that I work with. Even then, I figure it takes about an hour to tune and test it after a cartridge change. I never plan on loading with it the same day, I like getting it ready at my leisure, and then start work when everything is together.

- Ranch Dog

- Site Admin

- Posts: 6457

- Joined: 22 Jun 2013 17:16

- My Press Choice: Progressive

- Location: Inez, TX

- Has thanked: 1617 times

- Been thanked: 2850 times

Re: I'm All In ~ App Press Deluxe

Haah! Yeah, I think I know a bit about you, and you will get it.klr wrote:I sure am glad to read this. I spent several hours both Saturday and Sunday night setting up my Loadmaster. Nice to know it's not just me.

I will wander off-topic (APP) to the Load-Master, but it is along the lines of all the tool changing.

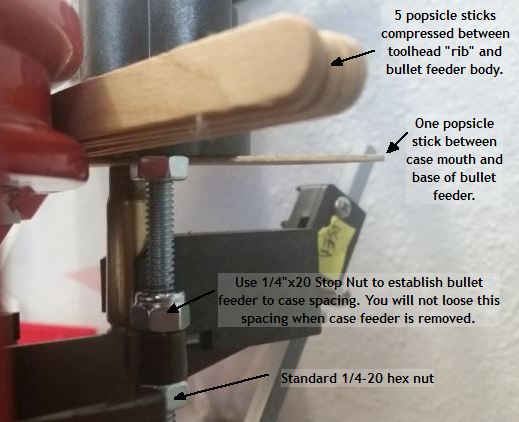

What it came down to for me is ending the fine adjustments that would affect ammunition, one lot to the next. That is the why behind all the duplicate parts such as bullet & case feeders. I don't adjust anything on the swap. The feeders use a stop nut for the exact position; I secure the bottom nut. If a case slider is different, it stays with the turret. Same with Auto Drum, etc. The result of this effort is that it didn't matter when the ammo was loaded; there is no variation in anything related to the reload. Everything is the same. If you move/share tools on the press, it is never precisely the same.

It is also why my Load-Master tool kit consists of three wooden specialty tools; a six-sided (hexagonal) pencil, a popsicle stick, and five popsicle sticks glued together. I don't need anything else to set up a press other than the wrench set I keep on the bench.

If I do a deep cleaning of the press to remove the ram, I do use a torque ratchet to adjust the draw bolt to the specified 11.6 ft lbs.

Michael

-

klr

- 250 Shots

- Posts: 305

- Joined: 01 Mar 2016 05:00

- My Press Choice: Single Stage

- Location: ohio

- Has thanked: 108 times

- Been thanked: 94 times

Re: I'm All In ~ App Press Deluxe

Dang, now you have me measuring pencils.  My instructions said 5/16" clearance. I used a drill bit and it worked fine, but I like your jam nut and popsicle method for quickly switching calibers.

My instructions said 5/16" clearance. I used a drill bit and it worked fine, but I like your jam nut and popsicle method for quickly switching calibers.

- Ranch Dog

- Site Admin

- Posts: 6457

- Joined: 22 Jun 2013 17:16

- My Press Choice: Progressive

- Location: Inez, TX

- Has thanked: 1617 times

- Been thanked: 2850 times

Re: I'm All In ~ App Press Deluxe

The drill bit is a great idea. I took a pencil from my grandson. It stays on the bench.

Michael