DIY Bullet Seating Stem

Posted: 14 Dec 2014 08:52

As part of my round ball project, I had to make a bullet seating stem for my Lee die set as the distance between the ball and a spec cartridge is just too different (stem too short). I keep 1/4" carriage bolts handy, 3 1/2" in length, as some of my round flat bullets don't lend themselves to the length of the factory seating stems either. I use the smooth shank of 1/4" carriage bolt.

With the die set up per it's instructions with the seating stem removed, I raise the cartridge into the die with the ram. With the depth "feature" of a caliper, I measure from the top of the die to contact with the cartridge.

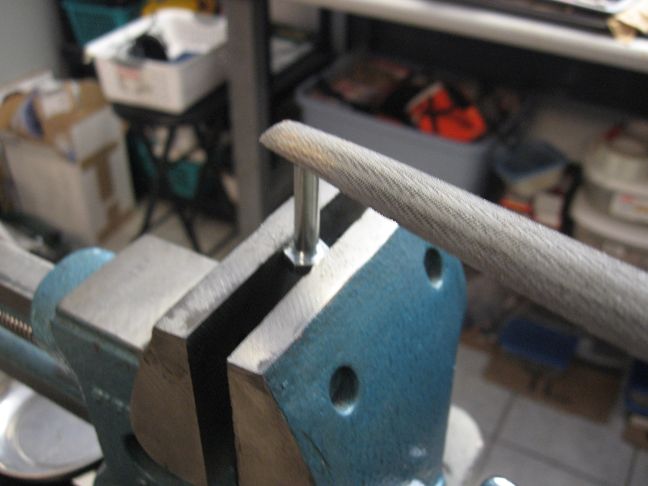

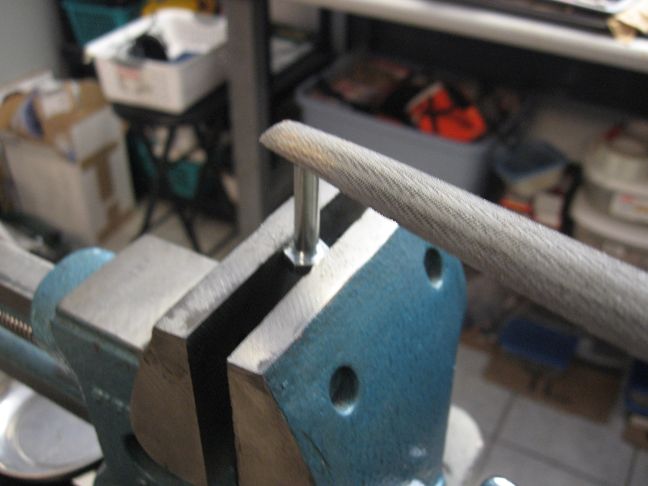

With my Lee dies, I subtract 1/4" from the measurement and mark the bolt from the top surface down the shank. Cut it with a hacksaw.

Not much effort from here. In that I shoot flat nose bullets and the round balls have flat nibs on them. I file it flat.

The Lee case debur and chamfer tool does a great job of beveling the edge of the flat surface.

From here, all you have left to do is drop the bolt stem into the die and adjust.

With the die set up per it's instructions with the seating stem removed, I raise the cartridge into the die with the ram. With the depth "feature" of a caliper, I measure from the top of the die to contact with the cartridge.

With my Lee dies, I subtract 1/4" from the measurement and mark the bolt from the top surface down the shank. Cut it with a hacksaw.

Not much effort from here. In that I shoot flat nose bullets and the round balls have flat nibs on them. I file it flat.

The Lee case debur and chamfer tool does a great job of beveling the edge of the flat surface.

From here, all you have left to do is drop the bolt stem into the die and adjust.